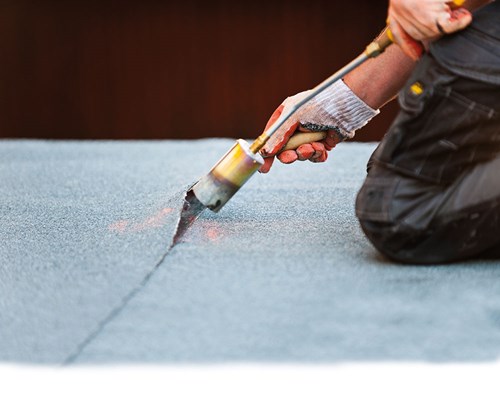

Gary Walpole, NFRC’s Health, Safety and Environment Officer, explains some of the main points that installers need to consider when carrying out hot works according to Safe2Torch principles.

In July 2017 the NFRC launched its Safe2Torch guidance. The aim was to get specifiers of waterproofing systems to highlight fire risks at the design phase and replace these details with a torch-free alternative. We wanted to encourage the specifier to consider the whole process from design and planning through to the installation of the actual work.

The Safe2Torch campaign has been a huge success and is recognised by the HSE’s Helping Great Britain Work Well campaign. Over 300 companies are now behind Safe2Torch, including major manufacturers such IKO, Sika, Proteus Waterproofing and contractors such as Longworth, Proctor and Everlast.

The next stage of the Safe2Torch campaign is to support the contractors working with gas torches by providing them with a Safe2Torch training module. The training module covers everything from storing and handling of LPG, to using the right tools and equipment, to fires watches and permits to work.

The module is supported by the Safe2Torch Safe System of Work and a pictorial checklist, which is available for download from www.nfrc.co.uk/safe2torch. The training module will in the first instance, be delivered by our member manufacturers alongside their membrane training courses.

This is a real opportunity for the NFRC and the industry to clearly show it understands the serious issue of fire in construction and that it is forward thinking and able to do something about it. So, what are the main points that contractors involved in hot works need to consider in order to ensure safety? Below are some key points from the Safe System of Work.

Handling LPG cylinders

Never use the LPG bottle cap, valve or shroud to lift the cylinder and never open the valve of an unconnected LPG cylinder as there is still likely to be some LPG left inside even on cylinders that appear empty.

Storing LPG cylinders

It is important that LPG cylinders are stored in the upright position and removed from the workplace when not in use and cylinders should be stored in a lockable gas cage when not in use.

Using LPG cylinders

The greatest hazard when working with LPG is that when mixed with air, it can burn or explode if there is a source of ignition. LPG containers are liable to explode if they are involved in a fire. Therefore, you should never subject the LPG cylinder to heat as this could increase the pressure inside and exceed the safe limit. This applies to empty cylinders as it does to full ones.

Connections

The regulator should be a left-hand threaded for fuel gases, with the hexagonal nut on the union connections notched to aid identification. It should also have a safety cut-off valve that stops the gas supply to the hose should the hose become damaged during use. After attaching the gas torch to the LPG cylinder, you should check all connections for leakage, using an approved leak detection solution.

Hoses

LPG hoses should be orange in colour and of a suitable length. Hoses are relatively vulnerable pieces of equipment, which are vital to ensuring a flow of gas to your torch. You should therefore select and store them with care.

Torches

Gas torches should be fitted with a stand to ensure the hot burner does not come into contact with the roof surface, or materials with the work area. Torches that self-ignite and extinguish by using an electronic ignition system are safer and use less gas. Gas torches that are manually lit, must be extinguish after use. Never, ever leave a gas torch running on a pilot flame.

Fire extinguisher

Fire extinguishers should be selected and have an up-to-date service record. It is important to select an appropriate fire extinguisher for the task. Depending on the types of material and risk involved, it may be necessary to provide more than one type of fire extinguisher.

Permit to work (PTW)

Never start hot works without a PTW in place. PTWs and fire watches MUST NEVER be seen as simply a tick- box exercise. Working within the permit needs to be as robust as the installation of the roofing membrane; it must be watertight. This means strictly complying with the hot work permit at all times after having the carried out a hot works inspection and ensuring all precautions required by the permit are in place, such as fire extinguishers.