Clay Preparation

Firing and Cooling

We extrude around 6,000 machine-made tiles an hour at our factory. However, ornamental tiles and fittings are all made by hand at a much slower rate. For example, 1,500 ornamental tiles, or 400 hips, are cut per day.

Extrusion

We extrude around 6,000 machine-made tiles an hour at our factory. However, ornamental tiles and fittings are all made by hand at a much slower rate. For example, 1,500 ornamental tiles, or 400 hips, are cut per day.

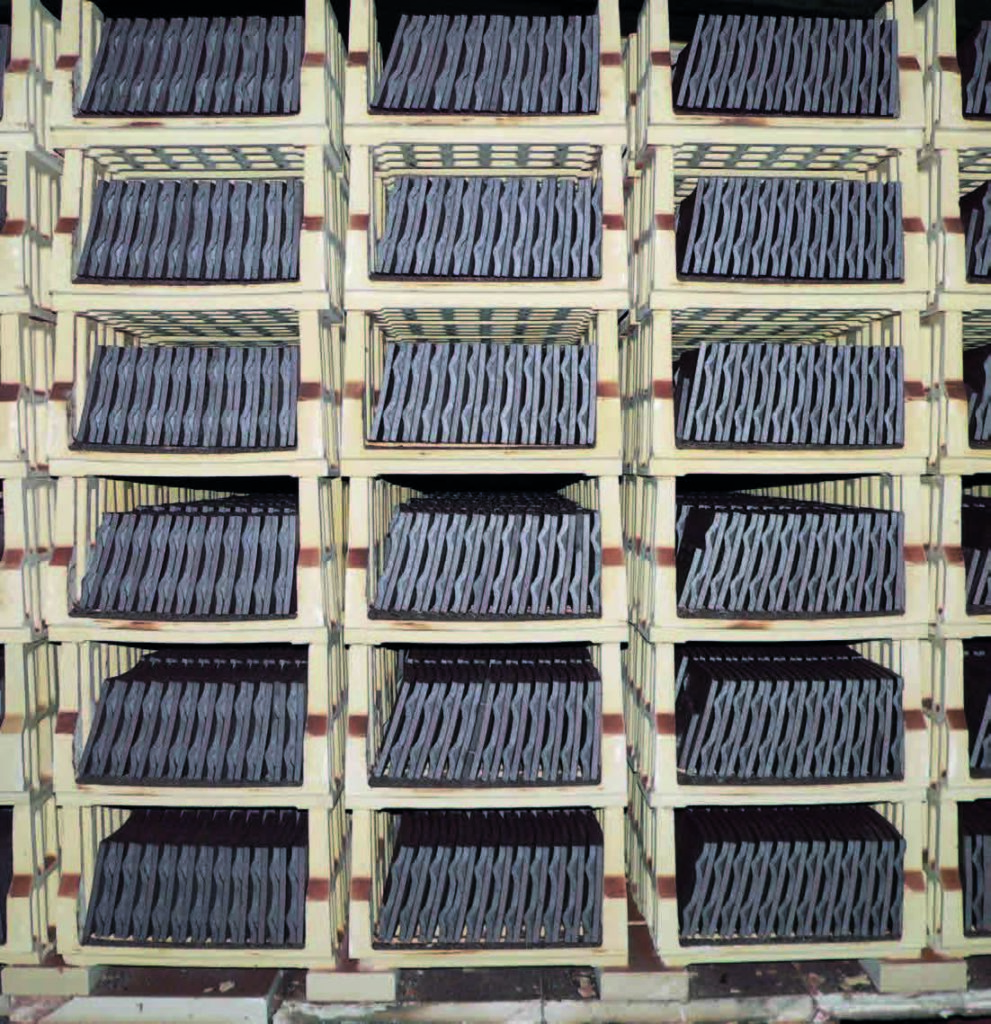

Drying

Drying tiles takes seven and a half days (gable tiles are bigger and take 14 days to dry). It is very important to dry them slowly so that the inside dries before the outside skin. If there’s any moisture left trapped inside the tiles, they will explode in the kiln.

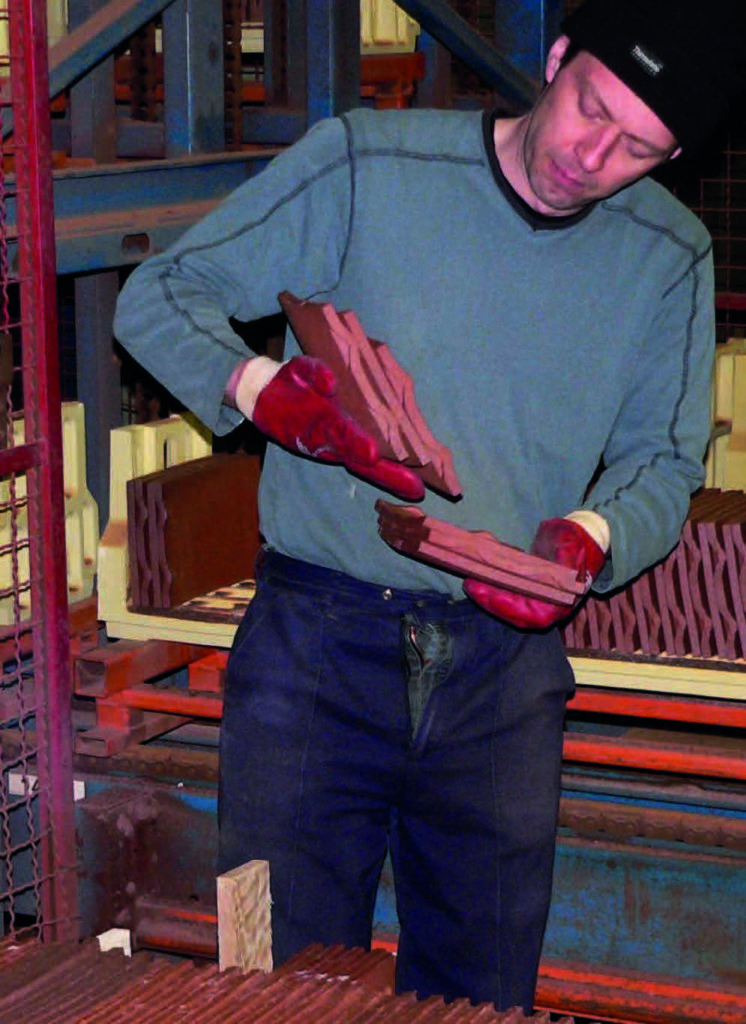

Quality Control

For more information please visit www.dreadnought-tiles.co.uk