FP McCann has recently opened a state-of-the art concrete roof tile manufacturing facility which will supply an extensive range of concrete roofing products to the housing and commercial sectors. The brand-new fully automated facility based at the Company’s Cadeby precast site near Nuneaton in Leicestershire, has the capacity to produce 60 million roof tiles per annum; it will also deliver impressive carbon reductions as it is 100% powered by solar panels.

The premium package of concrete tiles together with complementary accessories, are all designed and tested to British Standard BS5534 and compliant with NHBC construction guidelines.

FP McCann’s branded ”Thin Flat” and “Thin Flat Duo” tiles are thin leading edge interlocking concrete roof tiles which give a slate-like appearance when laid half broken bond. These modern looking low-profile tiles available in Anthracite Grey, Terracotta and Brown, feature a smooth non-textured finish and bullnose edge. The “Seawave” tile, is a standard profile concrete roof tile with a subtle soft-roll design. This classic double pantile feature lends itself to both traditional and contemporary styles.

Commenting on the new products, Jonathan Pratt, FP McCann’s National Roof Tile Manager says, “On the launch of our premium concrete roof tile range, we will guarantee the highest standards of quality whilst also providing the market with a low-cost solution to all their pitched roofing requirements. Following thorough testing for wind uplift and water resistance, FP McCann can confidently confirm that all three tile formats will be installable to a 17.5 degree pitch whilst maintaining integrity and water tightness when installed and fixed to BS5534 standards”.

Jonathan adds, “As part of our extensive package, we also have the “Multi-Ridge” concrete tile which can be fixed on both the ridge and hip of the roof. This universal ridge tile can be used with both the Thin Flat Tiles and the Seawave Tile and bonded using FP McCann’s own “FastDry Fix” systems, or alternatively, bedded with FP McCann Roof Tile Bedding Mortar in accordance with BS5534.

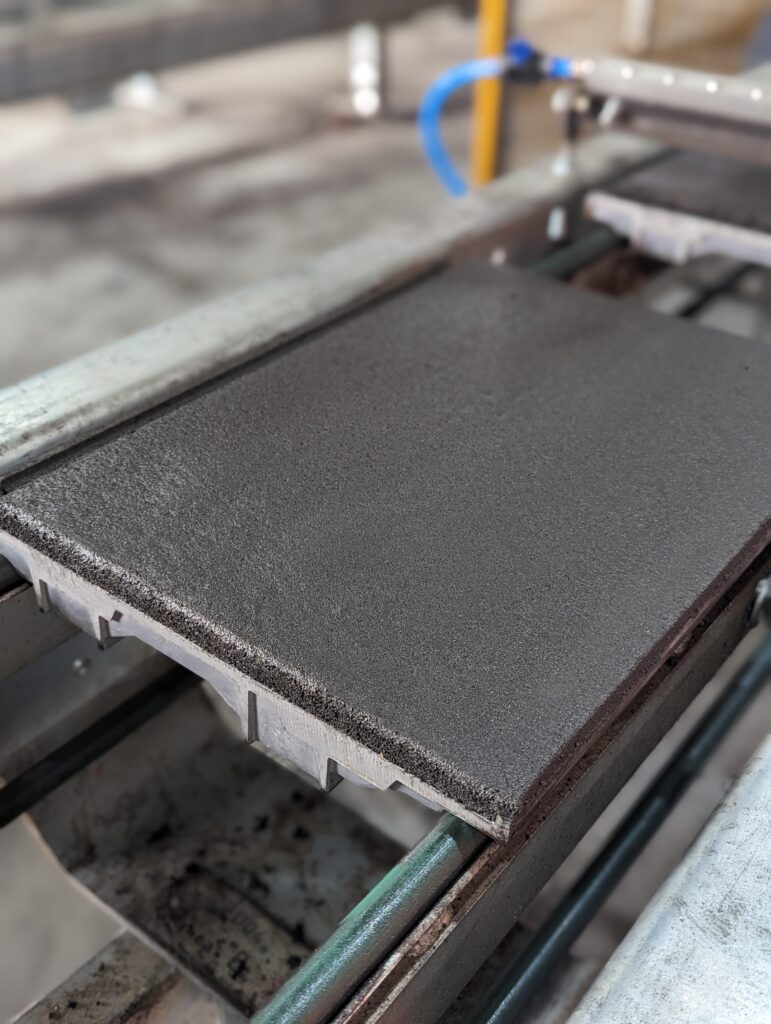

The latest concrete tile manufacturing equipment has been installed in the new factory: The process starts with the mixing of sand, cement, iron oxide and water in controlled measures in a planetary mixer to produce a semi-dry concrete composition. The semi-dry tile mix is then conveyed to a hopper, where it is extruded onto aluminium moulds and cut to the precise tile lengths. Each individual mould and tile are then automatically transferred at a rate of 140 a minute into a rotary curing system which is heated at between 40 and 50 degrees Celsius. Regulated air is circulated to control humidity and temperature levels to achieve the optimum curing time and initial tile strength.

The second stage of the continuous curing cycle sees the tiles loaded onto a large circular rack that slowly rotates until they reach an unloader. This process takes between 6-8 hours. Once unloaded each tile passes through an automatic demoulding machine that parts the tile from its mould. The mould is then returned to the first stage of the process.

The fully cured tiles then continue through a paint booth where two coats of acrylic water-based paint are applied to seal the tiles. A similar rotary racking system allows the paint to dry before the tiles are stacked on top of each other to form a pack of 38. The packs are finally relayed onto a strapping and palletising line and placed on wooden pallets. Extra protection is provided with a stretch hooding bag and a chain conveyor then transports the pallets into storage.

FP McCann also boast an extensive range of quality roofing accessories specifically chosen and designed to work in cohesion with all aspects of the full roof tile range, each being compliant with BS5534 and NHBC guidelines. The range includes dry fix solutions such as Handed Dry Verge to provide a mortar free and secure method of fixing, Dry Ridge & Hip Kits suitable for ventilating FP McCann’s “Multi Ridge”; the “McCannVent” tile which fits in line with the roof itself; Eave Ventilation Systems; 150gsm Vapour Permeable Membrane suitable for all wind zones regardless of fitting method; GRP Valley Troughs designed as a lightweight and durable solution and Fixings and Clips.