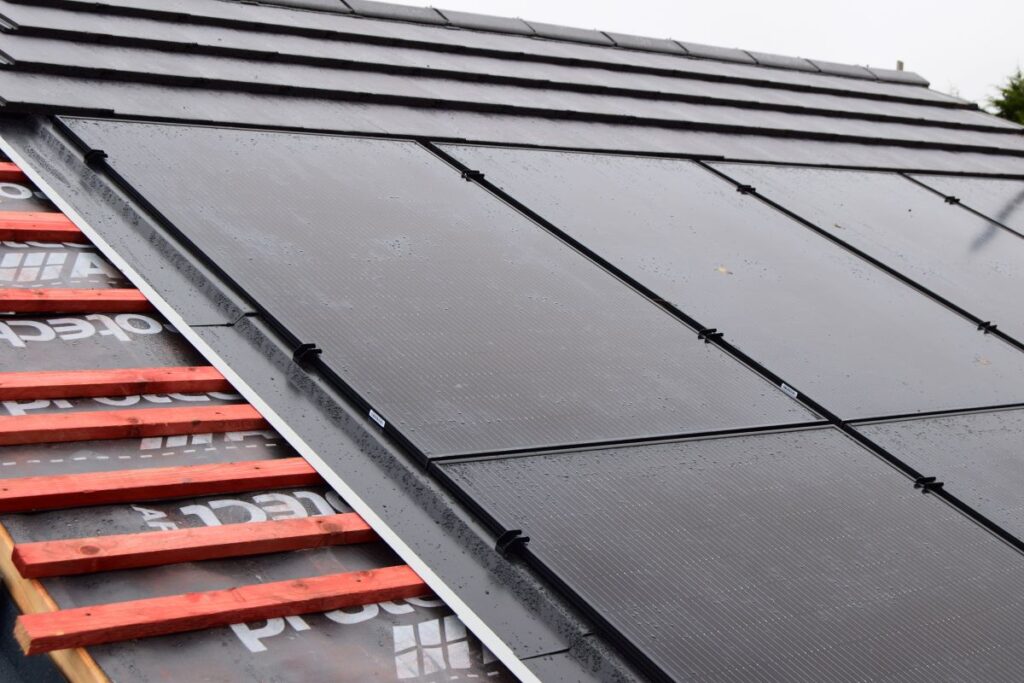

The use of solar PV is an area of growing importance as a way of meeting Building Regulations Part L requirements and ensuring energy efficiency measures are in place. Choosing the right underlay and ventilation for a roof which has integrated in-roof solar panels is fundamental to ensure risks of condensation are minimised. This can be challenging due to the abundance of information and varying recommendations from membrane suppliers in the market.

Glidevale Protect aims to simplify this process. While technically any type of membrane can be installed—whether it’s an air and vapour permeable membrane (LR) like Protect Viking Air, a vapour permeable (LR) membrane like Protect VP300 and VP400, or an impermeable underlay (HR) like Protect A1 Solar—the important factor is that the ventilation requirements can differ depending on whether it is a warm or cold roof as well as the underlay type that is ultimately chosen.

Glidevale Protect has answered some of the most commonly asked questions to help make things simpler for you. The FAQs cover everything from the different choice of pitched roofing underlays available and the associated ventilation strategies for an impermeable roof covering, in accordance with BS 5250 and the latest NHBC Standards.

Q. Is a roof with an array of integrated in-roof solar PV panels classed as permeable or impermeable?

A. In accordance with the latest NHBC Standards, which came into effect on January 1st 2024, there are revisions to clause 7.2.15 ‘Ventilation, vapour control and insulation’ which stipulates that where arrays of integrated in-roof solar roof panels are used, the whole roof covering should be treated as air impermeable unless the panel manufacturer is able to demonstrate its system is air permeable.

As a result, roofs with integrated PV panels will now be classed as air impermeable as standard, even if the roof tiles themselves are air permeable. So, a small number of PV panels would render the whole roof impermeable and should be treated as such, unless it can be proven otherwise. And as an impermeable roof covering, there is a greater risk of interstitial condensation forming on the underside of the external roof covering if the correct ventilation strategy is not used both above and below the membrane.

Q. If there is only a small array of solar panels on my roof, is there enough permeability in the tiles/slates to deem the roof covering permeable?

A. No, even if there is only a small array of solar panels on your roof, the latest NHBC standards classify the roof as impermeable due to the presence of integrated in-roof solar PV panels. Therefore, it is necessary to follow the appropriate ventilation guidelines to ensure compliance with BS 5250 requirements.

Q. I am installing integrated in-roof Solar PV panels, what underlay should I use?

A. Choosing the right underlay for a roof which has integrated in-roof solar panels can be challenging due to the abundance of confusing information and varying manufacturer recommendations.

Glidevale Protect aims to simplify this process. While technically any type of membrane can be installed—whether it’s an air and vapour permeable (LR) like Viking Air, vapour permeable (LR) like VP300 and VP400, or an impermeable underlay (HR) like A1 Solar—the important factor is that the ventilation requirements can differ depending on whether it is a warm or cold roof as well as the underlay type that is ultimately chosen.

Q. What is the difference between type LR & HR underlays?

A. LR (air & vapour permeable): An air and vapour permeable underlay is a type of LR pitched roofing membrane designed to allow both air and water vapour to pass through it whilst providing a barrier against water and wind. This type of underlay is typically used in roof constructions to enhance the breathability of the building envelope, reduce the risk of condensation, and improve overall ventilation. Protect Viking Air complies with the NHBC requirements for both cold and warm pitched roof constructions without the need for any additional ventilation. However, this is not applicable where in-roof solar panels are installed, as additional ventilation is then required.

LR: A vapour permeable underlay (also known as a low resistance underlay or LR) is a type of pitched roofing membrane designed to allow water vapour to pass through while providing a barrier against liquid water. A vapour permeable LR underlay is airtight, which means air cannot pass through the membrane. Roof space ventilation is required when using this type of membrane on an impermeable roof covering in accordance with BS 5250.

HR: A HR (high resistance) underlay, also known as an impermeable or non-breathable underlay, is a type of roofing membrane designed to prevent both water and water vapour from passing through it. It is a modern equivalent of the traditional 1F bitumen felt. This underlay creates a strong barrier against external elements, providing maximum protection for the roof structure. When using this type of underlay on either a permeable or impermeable roof covering, high and low-level ventilation is required to ensure adequate airflow within the roof space.

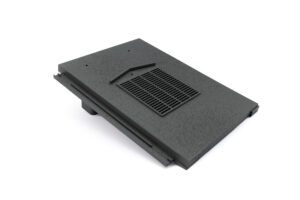

Q. What is Protect A1 Solar?

A. Protect A1 Solar is a high performance, heavy-duty type HR impermeable roofing underlay designed for use on all cold and warm pitched roofs, where in-roof solar PV panels are installed.

In addition to high and low-level ventilation, Protect A1 Solar provides a reliable solution to mitigate the potential for condensation under solar PV panels. Its high resistance to vapour transfer eliminates the necessity for a ventilated counter batten space above the membrane, resulting in savings in both time and material costs. By preventing moisture from passing through, an HR underlay like Protect A1 Solar significantly reduces the risk of moisture becoming trapped beneath solar panels, thereby minimising the potential for long-term damage and rotting roof timbers.

Q. Why does Glidevale Protect recommend using Protect A1 Solar or another HR underlay as one option when integrated in-roof solar panels are used?

A. The latest NHBC Standards categorise a roof with integrated in-roof solar PV panels as impermeable, irrespective of the amount of solar panel coverage. Consequently, our guidance aligns with that for installing fibre cement man-made slates, which are also classified as impermeable or airtight. Glidevale Protect advises that you can utilise any type of pitched roofing underlay with in-roof solar, but it is important that the ventilation strategy complies with the requirements specified in BS 5250.

However, there are added benefits to using an impermeable, high resistance (HR) underlay, such as Protect A1 Solar. In addition to preventing moisture from reaching the underside of the panels, HR underlays are generally less expensive than air-open or vapour permeable (LR) underlays, offering a cost-saving advantage to the end user.

Moreover, BS 5250 stipulates that when using an LR vapour permeable or air open underlay on a cold roof with an impermeable roof covering – such as where in-roof solar panels are installed and counter battens are not used, the roof space must still be ventilated below the membrane*, the same way an HR underlay would be. This requirement negates the additional cost of using an LR underlay over a HR, since ventilation is necessary below the membrane, regardless of the type of underlay used.

*As detailed within BS 5250, if counter battens are not used with an LR membrane on an impermeable roof covering, ventilation is required underneath the underlay for both cold and warm roofs. Cold roofs need 10,000mm²/m at eaves level and 5,000mm²/m at the ridge, with ridge ventilation required only when the roof pitch exceeds 35 degrees, spans over 10m, or has a mono pitch. Warm roofs require additional airflow, with 25,000mm²/m needed at eaves or low level and 5,000mm²/m at ridge or high level.

To assist you in identifying the correct ventilation needs for your project, you can use our handy visual guides or contact our Technical team for clarification.

Q. Can you use vapour permeable or air and vapour permeable (LR) roofing underlays with in-roof solar, without additional ventilation?

A. The simple answer is no, as the roof is classed as impermeable it will need further ventilation provision. When vapour permeable, low resistance (LR) roofing underlays, including air and vapour permeable membranes are used on a warm or cold roof in conjunction with integrated, in-roof solar PV panels, Glidevale Protect’s recommended best practice is to install counter battens. Using 25mm deep counter battens with a minimum free ventilation area of not less than 25,000mm²/m at eaves or low level and 5,000mm²/m continuous air gap each side of the ridge or at high level is advised. On a cold roof, ventilation is also required under the membrane at 7,000mm²/m at eaves level with a normal ceiling or 3,000mm²/m at eaves with a well-sealed ceiling.

Alternatively, it is also accepted to ventilate with 5,000 mm²/m at ridge instead of 3,000 mm²/m at eaves if there is a well-sealed ceiling. Without the use of counter battens with an LR underlay, the risk of interstitial condensation forming on the underside of the solar panels increases, as the water vapour will pass through the membrane but cannot escape into the atmosphere. One alternative option when using an LR underlay on a cold roof however, as detailed in BS 5250 is not to counter batten but ventilate underneath the underlay as if it was a HR underlay, thereby requiring eaves level ventilation plus additional ridge ventilation, the latter only required subject to the roof’s pitch, span and if classified as a mono pitch.

Q. Roof designs are much more complex today. Can you guarantee the proper control of condensation within a roof space when using an impermeable (HR) underlay?

A. Roof designs have become more complex in recent times, with the addition of dormers, hips, valleys, abutments, and in-roof solar panels. Additionally, modern construction techniques have made houses more airtight, and as people spend more time at home, the moisture levels within the home have increased. This elevated moisture can pass through the building fabric into the roof space, necessitating effective ventilation strategies to manage condensation, maintain a healthy roof environment and avoid the dew point being met.

Glidevale Protect’s Technical team can conduct a roof space condensation risk analysis (CRA) and develop a tailored roof space ventilation strategy for each of your solar projects to mitigate condensation risks when using an HR underlay, regardless of the complexity of the roof.

Please contact our Technical team for assistance.

Q. If I use an LR underlay, does/would the heat produced from PV panels help disperse trapped condensation into the atmosphere?

A. This is not guaranteed. Without a ventilated counter batten space, moisture that reaches the underside of the panels can become trapped and potentially cause roof timbers to rot over time. A ventilated counter batten space facilitates the dispersion of moisture into the atmosphere, where air is drawn in from low or eaves level and disperses at high or ridge level. This method ensures that any accumulated moisture is effectively removed from behind the panels, helping to preserve the integrity of the roof structure. Whilst not empirically proven, without a ventilated counter batten space, the additional heat generated from the solar panel which is then trapped underneath it, can increase the amount of vapour that can be held in the air, so if the temperatures drop and the dew point is met, the condensation risk can be even greater.

Q. What are the requirements of installing in-roof solar panels on a warm roof?

A. When installing integrated in-roof solar panels on a warm roof (room in roof), BS 5250 specifies that if a vapour permeable or air and vapour permeable (LR) underlay is used, a 25mm ventilated counter batten space is necessary. This ventilation must be above the membrane and needs to incorporate 5000mm²/m of ventilation at ridge level.

If an impermeable (HR) underlay is used, a ventilated counter batten space is not required, which saves time and material costs. However, ventilation is needed below the membrane, with 25,000mm²/m required at eaves and 5,000mm²/m at ridge, as well as a clear 50mm ventilation path being provided between the membrane and the insulation.

More detailed ventilation guidance can be found in our technical ventilation flow chart documents or by consulting with our Technical team.